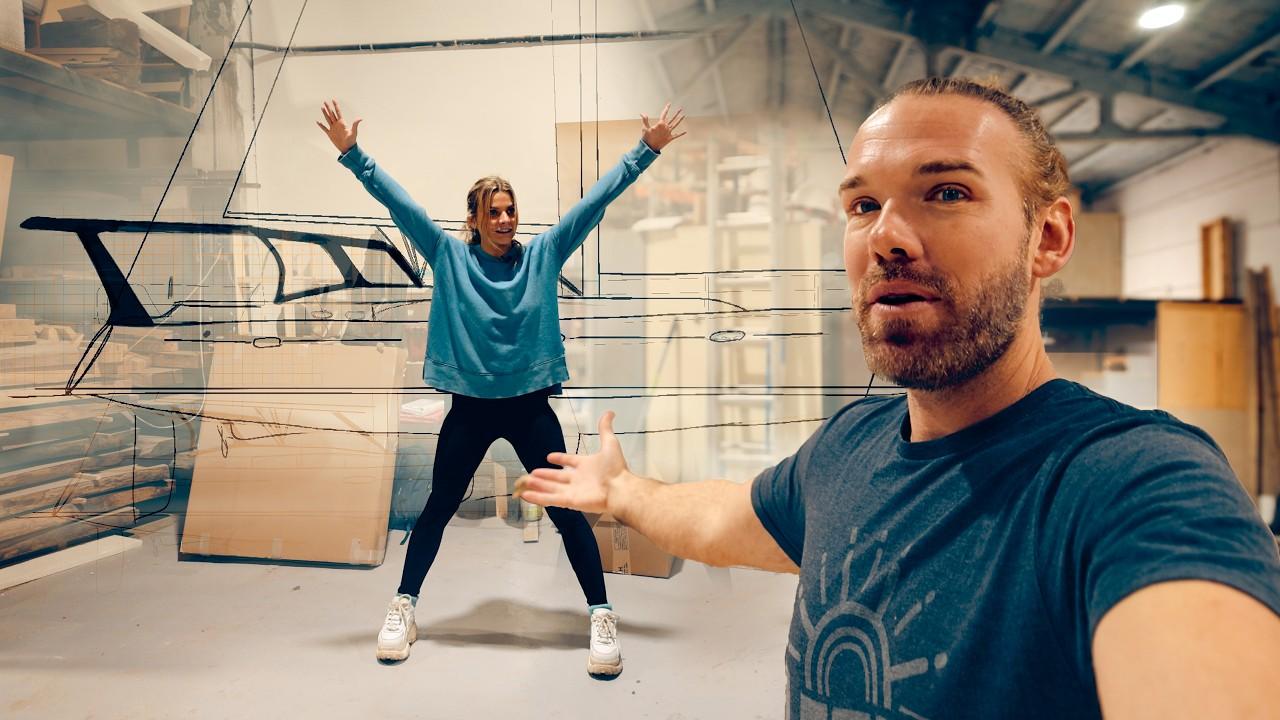

Welcome to our blog post, where we dive into the thrilling and eventful world of Expedition Evans 11. In this YouTube video, titled “Our Keel Gets RIPPED OFF! (and so do we)”, we witness a series of unfortunate events that unfold due to the presence of one person from the corporate side of things. But before we delve deeper into the chaos, let us be crystal clear – we hold nothing but love and admiration for our boatyard and its crew. They have treated us exceptionally well, and we trust them implicitly. What you are about to witness is not their fault; they too are victims of circumstance.

Now, let the adventure begin! Join us on our journey as we discover and acquire our dream boat, only to face the daunting task of putting her back together. The anticipation builds as the keel drop approaches, but first, we must gather the necessary tools and materials. We acquire a solid blade to dismantle the keel’s connection, and we search for the perfect tarp to keep the dust at bay during the grinding process.

In the midst of our preparations, the yard crew surprises us with the news of a slight setback – a tweak in the keel stand, requiring immediate attention. Nevertheless, we press on, tidying up the deconstructed salon and loosening the bolts in anticipation of the upcoming keel drop. Time is money, after all, and we aim to minimize both as much as possible. With fingers crossed, we continue loosening the bolts, hoping for smooth sailing ahead.

But why stop at the keel? We seize the opportunity to also inspect and potentially replace the bushings in our rudder. However, to ensure a perfect fit, accurate measurements are necessary. With the rudder disconnected and the scaffolding dismantled, our boat awaits the crucial moment when the keel and rudder will be dropped, marking a significant milestone on our expedition.

So buckle up and prepare for an exhilarating ride filled with unexpected twists and turns. As we navigate the challenges of rebuilding and repairing, we invite you to join us on our greatest adventure yet. Together, we strive to breathe new life into our beloved vessel and embark on a voyage of a lifetime. Stay tuned for the twists and turns that await us in the continuation of Expedition Evans 11!

– Introduction: The Background and Misunderstanding

In this section of the post, we want to provide some background information and address any misunderstandings that may arise from the content of the video transcript. Firstly, we want to emphasize our love for our boatyard and the people who work there. The crew has always treated us well and we have developed a strong bond with them. We trust them completely and want to make it clear that they are not at fault for any of the upcoming events. The unfortunate situations that will be shown in the video are solely due to one individual from the corporate side who was temporarily involved in the yard.

It is important to acknowledge that the real victims here are the yard crew members. They had to endure working with this person for a long time, and we empathize with their experiences. However, now that we have clarified this, we can move forward with the video and show you all the events leading up to the keel drop. Despite the challenges, we have found our dream boat and are excited to share our journey of restoring and embarking on our greatest expedition yet. Mistakes happen, but we are determined to put our boat back together and set off on our adventure.

In the upcoming segments, you will witness us preparing for the keel drop. We have acquired a solid blade to cut the connecting 5200 for the keel. Additionally, we will be searching for a recommended plastic tarp to minimize dust during the process. The yard crew has kindly informed us that they will fix one of the legs on the keel stand before the drop. This ensures safety and stability during the procedure. As we continue with the preparations, we will be loosening the bolts to save time and money. However, we will make sure to maintain the necessary structural stability. Our goal is to make the process as smooth as possible, removing the bolts and possibly cutting the sealant underneath for a successful keel drop. Furthermore, we have decided to inspect our rudder during this time and potentially replace the bushings. To ensure the rudder posts drop properly, we measured and requested an extra three feet of lifting. Stay tuned as we document this exciting and transformative phase of our boating journey.

– The Keel Drop Process: Preparation and Challenges

In preparation for the keel drop process, we made sure to gather the necessary tools and equipment. We obtained a solid blade for cutting the 5200 that connects the keel, and we also went to look for a recommended plastic tarp to keep the dust out during the process. Additionally, we received great news from the yard crew that they would be fixing one of the legs on the keel stand to ensure stability before the drop.

To save time and money, we started loosening the bolts before the crew arrived. While we couldn’t loosen them too much for structural reasons, we aimed to have them ready for a faster process once the drop began. Thankfully, the bolts were coming out easily so far, and we planned to remove them all and cut the sealant underneath for a smooth keel drop. We also took this opportunity to inspect and potentially replace the bushings in our rudder, ensuring that everything was in top shape for our upcoming expedition.

As the crew prepared to drop our keel and rudder, we measured the necessary height for the rudder posts to drop all the way down to the bottom of the boat. After disconnecting the steering components and autopilot, we were left with just one bolt holding the shaft in place. With everything properly disconnected and measured, we were ready for the keel drop process to begin. Stay tuned to see the progress and challenges we face along the way!

– The Importance of Proper Equipment and Support

In order to successfully complete any task, it is essential to have the proper equipment and support. This becomes even more crucial when it comes to boat repairs and maintenance. The video mentioned earlier highlights the importance of having reliable equipment and a supportive crew in the boatyard.

Firstly, it is important to acknowledge the yard crew and their dedication to their work. The post emphasizes that the crew is trustworthy and provides excellent support to the boat owners. However, the negative experiences mentioned in the video were a result of one individual from the corporate side, who temporarily joined the yard. It is essential to differentiate between the crew members who are dedicated and the corporate involvement that led to certain problems.

Moving on, the post delves into the importance of having the right equipment for the task at hand. In the video, the boat owners acquired a solid blade to cut the 5200 that connects the keel, as well as tarps recommended by a professional fiberglasser to minimize dust. These equipment choices were crucial for the successful completion of the boat repairs. Furthermore, the post highlights the significance of the yard crew’s actions in ensuring the process runs smoothly and efficiently. The crew not only fixed a leg on the keel stand to ensure stability but also provided guidance on how to prepare for the keel drop. Their expertise and assistance contribute to a more streamlined and cost-effective repair process.

To conclude, the video and subsequent content emphasize the importance of using proper equipment and receiving adequate support in the boat repair and maintenance process. By acknowledging the significance of reliable equipment and a supportive crew, boat owners can ensure a successful and efficient repair journey.

– The Rudder Inspection: Ensuring Safety and Performance

In preparation for the keel drop, we decided to take the opportunity to inspect and potentially replace the bushings in our rudder. We wanted to ensure the safety and performance of our boat, so we disconnected the steering components and measured the height we needed to lift the boat for the rudder posts to drop down to the bottom.

Once we had the measurements, we began loosening the bolts on the rudder for easier removal during the keel drop. While we couldn’t loosen them too much for structural stability, we aimed to speed up the process to minimize the time spent in the slings and reduce costs. We also planned to cut the sealant underneath the rudder to facilitate its removal.

With everything set for the keel drop, we eagerly awaited the yard crew to come and fix one of the legs on the keel stand for better stability. In the meantime, we started tidying up our half-deconstructed salon and made preparations for the rudder inspection. We were excited to see what the inspection would reveal and potentially make any necessary repairs to keep our boat in its best condition. Stay tuned for the upcoming update on the keel drop and rudder inspection! In conclusion, we want to clarify that our love and respect for our boatyard and its crew remain unwavering. The unfortunate events that transpired were not a result of their actions, but rather the result of one individual from the corporate side who temporarily joined the team.

With that being said, we can now delve into the heart of the matter. The highly anticipated keel drop is finally happening, albeit with a few hiccups along the way. We have come across our dream boat, albeit in a slightly wrecked state, but fear not, as we invite you to join us on this incredible journey of restoration and embark on our greatest expedition yet.

As we make preparations, including acquiring the necessary tools such as a solid blade to cut the 5200 connecting the keel, we are also on a hunt for tarps recommended by a professional fiberglass expert to keep the dust at bay during the grinding process. The yard crew has been incredibly supportive, even going above and beyond by fixing a slight issue with the keel stand, ensuring a smoother operation.

Amidst the chaos of a half-deconstructed salon, we are excited to loosen the bolts, making way for a faster keel drop. However, we must balance this with maintaining the structural stability of the boat. It is our hope that by doing so, we can minimize the time spent in the slings and ultimately reduce the financial burden.

In addition to the keel, we have also decided to inspect and potentially replace the bushings in our rudder. To ensure accuracy, we have measured the height that needs to be lifted, allowing the rudder posts to descend seamlessly to the bottom of the boat.

As we bid farewell to the rudder, disconnecting various components, we eagerly await the moment when the keel will drop off. It is an intricate process, but with determination and the support of our trusted boatyard, we know that we are on the right track.

Stay tuned for the continuation of this incredible adventure, where we confront challenges head-on and witness the transformation of our beloved vessel. Thank you for joining us on this unforgettable journey of discovery and restoration. Until next time!