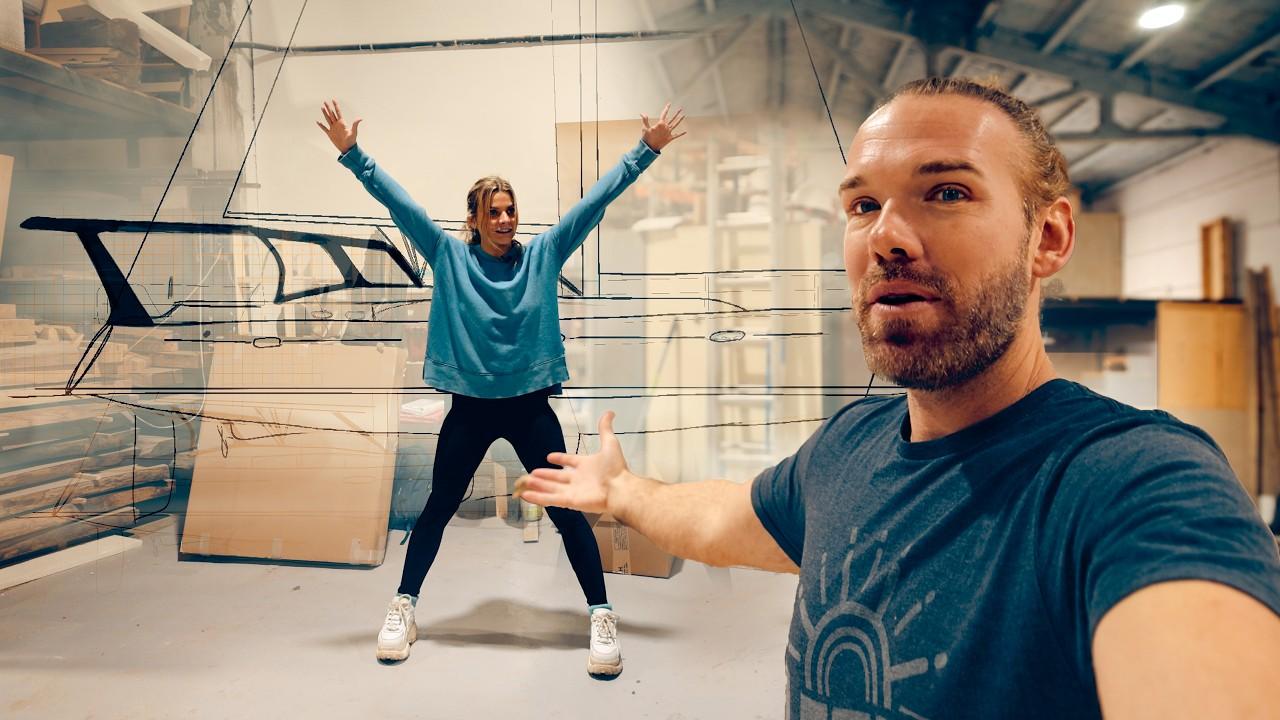

In the latest episode of Expedition Evans, our young couple tackles the challenging task of salvaging their sailboat during the midst of a global pandemic. With a determination fueled by their recent unemployment, they have successfully gutted a large portion of their boat to access the damaged areas. Now, their main obstacle is the thick layer of gel coat that stands in their way. Armed with six angle grinders and countless flap disks, they take on the daunting task of grinding away the gel coat. However, it’s not all smooth sailing as the process creates a cloud of dust that seems to infiltrate every corner of the boat. To protect the rest of the boat, they construct a plastic barrier, but their real challenge lies in finding the necessary personal protective equipment (PPE). With respirators and painting suits in high demand, they struggle to find the right gear to protect their lungs. Despite the setback, they manage to find a small victory and secure the necessary PPE, allowing them to continue their laborious task. With plastic wrap covering the majority of the boat, they eagerly anticipate the day of grinding and sanding ahead, comparing the experience to building forts as children. As they prepare for the next day, they reflect on the challenges they’ve already overcome and brace themselves for the emotional and physical demands that lie ahead. Stay tuned as they continue their salvage journey, one step at a time.

– Gutting the Boat: Removing the Satay and the Nav Station

In the previous episodes, we made progress in gutting our boat to access the damaged areas beneath the satay and the nav station. Now, our main obstacle is the thick layer of gel coat that we need to remove. To tackle this task, we are using our boot determination and utilizing six angle grinders, along with numerous flap disks.

However, grinding the gel coat creates a massive cloud of white dust that ends up getting on everything, similar to how politics can disrupt an unsuspecting dinner party. To protect the other areas of the boat, we are constructing a plastic barrier. The real challenge for us is acquiring the necessary personal protective equipment (PPE) for this job. We are searching tirelessly for respirators, painting suits, and gloves but finding them is proving to be difficult.

Despite the setback, we managed to find a hardware store in town that had a few painting respirators in stock. We quickly grabbed them along with extra coveralls. Feeling victorious, we eagerly prepare for the next day. We have set up plastic wrap throughout the boat, except for the front bedroom and companion way, which we plan to tackle in the morning. This whole process has surprisingly been fun, reminiscent of building forts as kids. However, instead of using the protective clothing provided, we end up with holes in our clothes that need patching. As we gear up for a long day of grinding and sanding, we can’t help but wonder if we are emotionally prepared for the challenges ahead. Despite some orthodontical challenges with a crossbeam and the excessive sealant, we managed to remove it and anticipate cleaning and sanding the area once the batteries are out. Tomorrow will be a new day full of hard work and determination as we continue our boat renovation journey.

– Challenges of Grinding Gelcoat: Dust and Protection

Grinding gelcoat can pose various challenges, with one major issue being the creation of a large white cloud of dust. This dust has a way of finding its way into every nook and cranny, much like a controversial topic discussed at a dinner party. To protect the rest of the boat from the dust, we are taking the necessary steps to create a plastic barrier. This barrier will help contain the dust and prevent it from spreading to other areas.

Another challenge we faced was finding the appropriate personal protective equipment (PPE) for the job. We quickly realized that locating a respirator, painting suits, and gloves was not as easy as we initially thought. After searching high and low, we were fortunate enough to find a hardware store that had some painting respirators in stock. We were relieved to finally have the necessary PPE to ensure the safety of our lungs during the grinding process.

As we set up the plastic wrap and prepare for a long day of grinding and sanding tomorrow, we can’t help but reminisce about our childhood days of building forts in the living room. This experience has been surprisingly enjoyable, despite the challenges we encountered along the way. We are excited to tackle this next step in our boat renovation journey and continue working towards our goal.

– Finding the Right PPE: A Small Victory

In the previous episodes of our reality show, we have been working diligently on our boat refurbishment project. We have successfully removed the satay and nav station, revealing the damaged areas that lie beneath. However, one formidable obstacle remains – the thick layer of gel coat. But fear not, our determination knows no bounds, as we armed ourselves with six angle grinders and an abundance of flap disks to tackle this challenge.

The process of grinding the gel coat, however, presented its own set of challenges. It created a massive white cloud of dust, infiltrating every nook and cranny of our boat. To mitigate this issue, we ingeniously built a plastic barrier to protect the unaffected areas. However, our real struggle lied in finding the personal protective equipment (PPE) necessary for this job. Our search for a respirator, painting suit, and gloves proved futile, leaving us dejected. But amidst the disappointment, a small victory emerged. We managed to find a local hardware store that had a limited stock of painting respirators. We quickly acquired a couple for ourselves, along with additional coveralls, and celebrated this triumph.

The preparations for the grind continued to unfold, with plastic wrap meticulously placed throughout our boat, resembling a set from "Breaking Bad." The front bedroom and companion way would require attention in the morning, ensuring that everything was ready for the grinding process. Despite the challenges and setbacks, this project proved to be surprisingly fun, reminiscent of our childhood days of building forts. However, this time, we were armed with plastic instead of our mom’s disapproving looks. As we geared up mentally for the long day of grinding and sanding ahead, we couldn’t help but reflect on the journey thus far. Though we encountered a few ordeals, such as breaking the wood to remove a crossbeam, we remained determined to see this project through.

– Preparing for Grinding: Plastic Wrap and Fort-Building

In our previous episodes, we tackled the task of gutting the living area of our boat, removing the satay and the nav station to access the damaged areas beneath. Now, we are faced with the challenge of grinding away the thick layer of gel coat that covers the boat. We are armed with six angle grinders and numerous flap disks to get the job done. However, grinding gel coat creates a massive cloud of white dust that settles on everything, much like a controversial topic infiltrating an unsuspecting dinner party. To prevent this dust from spreading to other areas of the boat, we have decided to build a plastic barrier.

Finding the necessary personal protective equipment (PPE) has proven to be another challenge. We have searched high and low for respirators, painting suits, and gloves to protect ourselves from the dust and chemicals. Unfortunately, we haven’t had much luck. The local hardware store was also devoid of these items. However, we managed to secure a few respirators, coveralls, and masks. Although it may not be ideal, it’s a small victory that will offer some protection during the grinding process. With the PPE in hand and the plastic barrier securely set up, we are almost ready to begin the grinding process. It’s reminiscent of building forts as kids, except this time, we’re using plastic wrap instead of sheets and blankets. It’s been surprisingly fun, despite the challenges we’ve faced so far. Tomorrow will be a long day of grinding and sanding, and we are mentally preparing ourselves for the task at hand. In conclusion, in our latest YouTube video titled "We DIG into our SALVAGE SAILBOAT | Expedition Evans 7," we embarked on a new challenge of removing the damaged areas of our boat. With determination and the help of multiple tools, including angle grinders and flap disks, we tackled the thick layer of gel coat that stood in our way. However, grinding the gel coat created a huge cloud of dust, which led us to create a plastic barrier to protect the rest of the boat.

One major challenge we faced was finding the necessary personal protective equipment (PPE) for this job. Despite searching tirelessly, we struggled to find painting respirators, suits, or gloves. Nevertheless, we managed to secure a few respirators and coveralls, which was a small victory.

With everything in place, including the plastic wrap set up, we are just about ready to begin the grinding and sanding process. This experience has been surprisingly enjoyable, reminiscent of building forts as kids. However, tomorrow will be a long day filled with challenging work.

Throughout this episode, we encountered some obstacles, such as the difficulty of removing a cross beam due to the excessive sealant holding it together. Nonetheless, we managed to overcome it and look forward to cleaning and sanding the area.

Stay tuned for the next episode of Expedition Evans, where we delve further into the restoration process of our salvage sailboat. Thank you for joining us on this incredible journey, and we appreciate all the support and encouragement. Don’t forget to like this video, subscribe to our channel, and leave a comment sharing your thoughts and suggestions. See you in the next episode!